Actyx’s mission is programming collaborative systems for machines and humans. Machines and humans work together with increasing autonomy and their interaction creates tremendous value which is why Actyx creates the tools to construct this collaboration. The smartphone has become a daily companion and so will the machine working next to you. For operational value and boosting teamwork, we must communicate horizontally with our neighbors, be that in physical proximity or when collaborating on the same task. Two of their famous products facilitate the company’s mission to provide a simless technical control in the workplace; ActyxOS – a multi-device operating system and Actyx Pond – a typescript framework for writing distributed apps.

At Techmeetups we are glad to announce that the team will be joining us for the Munich Tech Job Fair.

Grab your free ticket here.

Read below to get an insight into the heart and vision of Actyx

The case for a step-by-step digitization journey

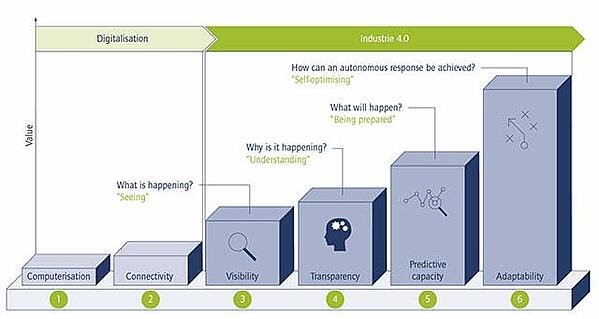

Achieving Industry 4.0 requires much more than simply connecting all your factory’s devices to the internet. It’s a process that requires an entirely new approach to business and operational processes, enabled by robust technologies. Acatech’s Industry 4.0 Maturity Index offers an excellent means for visualizing the process of digitalization, which illustrates it as a series of steps.

Many manufacturing SMEs are ready to tackle that first step, digitization (also known as digital enablement). Just as the entire journey to Industry 4.0 can be broken down into discrete steps, digitization should also be achieved step by step, rather than all at once. This approach is an ideal way to proactively manage the implementation of Industry 4.0 technologies for multiple reasons.

|

Acatech’s model for achieving Industry 4.0 presents the process as a gradual one, with distinct steps. |

More than merely an IT project

The journey toward Industry 4.0 requires more than just an IT project. Although Industry 4.0 might be enabled by a variety of hardware and software, the success of an Industry 4.0 initiative relies on the organization’s ability to change its business processes.

Take, for example, the automation of machine data collection, a common first step in digitization. This can help a maintenance team transition from preventative maintenance (which often requires unnecessary scheduled downtime) to predictive maintenance, an approach where machines receive maintenance only when the data reveals an operational irregularity.

Thus it is important to consider each Industry 4.0 initiative as a dual-pronged endeavor: you are introducing both a new technology and a new technology-enabled business process. Tackling digitization one step at a time makes it easier to successfully navigate both these aspects of the initiative simultaneously.

Critical role of user acceptance

With any IT project, success depends on end users. Do they understand the purpose of the new technology? Are they enthusiastic about using it? Do they understand how to use it effectively and efficiently, with a reasonable amount of training? And temporary workers, who are vital to manufacturing operations, quickly adopt the technology on the production line?

These same questions certainly apply to Industry 4.0 technologies. Furthermore, Industry 4.0 technologies may be perceived as a threat by line workers, who might fear that they will lose hours due to increased production efficiency, or even literally be replaced by robots.

Overcoming these potential issues requires a robust change management strategy that places user acceptance at its center. The introduction of too many new initiatives can undermine them all by overwhelming users with too many changes at one time. In contrast, the thoughtful, seamless implementation of a single Industry 4.0 effort can help end users understand the benefits of the new technology and make them more enthusiastic for the next initiative. This approach also precludes some of the usual issues that plague big IT projects–such as implementation delays, regular interruptions, and bugs–that can negatively impact user acceptance.

Potential for quick wins

A smaller project is more likely than a larger project to be completed on time, stay within budget, and produce the desired outcome. That alone can be sufficient reason to take digitization one step at a time. Moreover, an incremental approach also provides an opportunity to achieve a quick win that can then be scaled across the organization. For instance, the implementation of manual work logging might immediately help identify bottlenecks–reducing lead times, improving OEE, and increasing on-time deliveries.

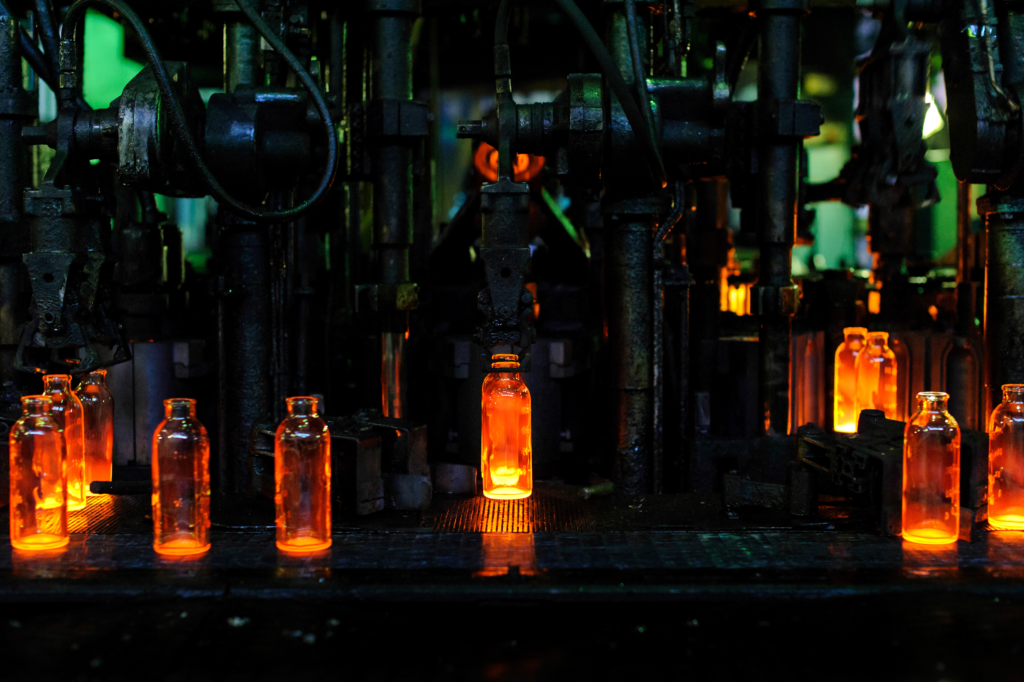

The key to attaining meaningful quick wins is to focus on a specific business problem or use case, and choose an appropriate technology to address it. A contract packaging organization might concentrate on the challenge of increasing machine uptime in a production environment that calls for frequent setups and job changes. Conversely, a glass manufacturer might look to reduce parameter variations that negatively impact quality.

Best practices for the first steps on the journey to Industry 4.0

Embracing Industry 4.0 currently offers a competitive advantage in many sectors of the manufacturing industry, but soon it will become necessary for manufacturers’ survival. Now is the time for SMEs to begin that journey. Keeping a few best practices in mind can increase the odds of successfully progressing toward Industry 4.0.

- Choose a business problem you can solve quickly without breaking the bank. Start conservatively not only with the scope of your project, but also with your budget. This way you can minimize the financial risk of the project, while also demonstrating ROI almost immediately.

- Define the full scope of the project. Remember that scope includes implementing not only new technology, but also the connected business processes.

- Be realistic about potential benefits, including ROI. Before embarking on any Industry 4.0 project, take some time to determine the benefits of the project and calculate the ROI. Be sure to translate operational value into business value and vice versa, so all stakeholders will have meaningful goals and metrics for the project.

- Evaluate actual benefits and ROI and adjust accordingly. Compare the expected outcomes to the actual outcomes. Adjust your plan based on the actual benefits realized by the project.

- Scale through iterations. Once the initial project has proven successful, the organization can digitally scale and achieve a first step in end-to-end digitization.

Easing into Industry 4.0 incrementally is ideal because a step-by-step approach allows room for changing business processes, ensuring user acceptance, and enjoying quick wins.

Find Actyx on Website | Facebook |Twitter

Looking for a job, your next co-founder or recruiting your tech talent? the Munich Tech Job Fair 2020 is an event to attend. Visit Tech Events for more information about the events and how you can get more out of the experience and also get yourself a ticket to an event!

Website: Techmeetups.com visit and treat yourself to a community of tech business events and support!

TechMeetups.com 8 years. 21 cities. 68 job fairs. 1100+ hiring companies. 60,000+ job seekers.